Top Factors to Choose Spray Foam for Your Next Insulation Job

When considering insulation choices for your next project, spray foam stands out due to its remarkable performance qualities and efficiency advantages. As you consider your selections, checking out the versatile applications and long-term advantages of spray foam may reveal compelling factors to integrate it right into your insulation approach.

Superior Insulation Efficiency

The high R-value of spray foam, which measures its thermal resistance, is an additional essential advantage. Closed-cell spray foam, as an example, can achieve an R-value of up to 6.5 per inch, substantially surpassing fiberglass batts and cellulose. Spray foam insulation develops an airtight seal, which decreases thermal bridging and reduces the capacity for mold and mildew development due to moisture build-up.

Power Effectiveness Conveniences

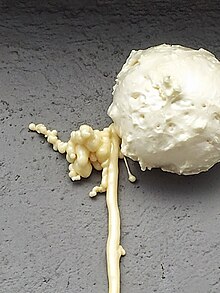

The energy performance advantages of spray foam insulation are considerable, more improving its charm as a top choice for constructing insulation. Spray foam increases upon application, producing an impermeable seal that decreases air leaks, which is a common resource of energy loss in typical insulation materials.

Furthermore, spray foam insulation flaunts a high R-value per inch, which implies it provides a lot more thermal resistance in less area contrasted to options like fiberglass or cellulose (Spray Foam). This efficiency not just adds to prompt energy savings however additionally advertises long-term sustainability by decreasing the total power consumption of a structure

In addition, the application of spray foam can qualify home owners for energy efficiency incentives and tax obligation credit scores, including economic advantages to its energy-saving capacities. In an age where power preservation is critical, selecting spray foam insulation not only boosts convenience yet likewise straightens with ecologically responsible methods, making it a sensible selection for both commercial and domestic jobs.

Dampness and Mold Resistance

Given its distinct structure and application technique, spray foam insulation offers exceptional wetness and mold resistance, making it a perfect selection for various environments. The closed-cell framework of spray foam produces a strong barrier that efficiently seals off prospective dampness access, therefore decreasing the chance of mold development. Unlike conventional insulation materials, which can take in water and give a reproduction ground for mold and mildew, spray foam continues to be unsusceptible dampness, improving the total health and wellness of the interior setting.

In addition, the application procedure of spray foam entails broadening and loading voids and splits, making sure a tight seal that lessens air leaks. This characteristic not only improves power effectiveness however also aids control moisture levels within the area. Proper moisture control is vital for preventing mold and mildew, making spray foam insulation especially helpful in areas susceptible to dampness, such as basements and crawl rooms.

In enhancement to its moisture-resistant residential properties, spray foam is likewise useful site inherently resistant to mold and mildew growth. This characteristic ensures that structures and homes remain secure and healthy and balanced in time, supplying satisfaction to home owners and building supervisors alike.

Long-Term Expense Savings

Buying spray foam insulation returns substantial long-term cost financial savings, primarily through improved power efficiency. Unlike typical insulation products, spray foam creates an airtight seal that reduces air leak. This reduction in drafts causes reduce cooling and heating costs, as a/c systems do not have to work as difficult to preserve comfortable indoor temperature levels.

Furthermore, the premium shielding residential or commercial properties of spray foam indicate that homes stay constantly comfy year-round, reducing dependence on energy-consuming home appliances. Over time, these savings can collect, resulting in an obvious decrease in energy costs.

Furthermore, spray foam insulation adds to the durability of your home's framework by preventing wetness buildup and mold growth, which can lead to costly repair services. With its resilience and resistance to clearing up, spray foam maintains its efficiency throughout the years, ensuring that the first financial investment continues to pay off.

Essentially, choosing spray foam insulation not only enhances your home's energy efficiency but additionally converts right into significant long-term economic benefits, making it a wise financial investment for homeowners wanting to minimize prices while enhancing comfort and sustainability.

Versatile Application Choices

Various application options make spray foam insulation a very functional option for a variety of structure jobs (Spray Foam). This adaptability enables it to be properly made use of in domestic, industrial, and industrial setups, satisfying varied insulation needs

Spray foam can be used in attic rooms, wall surfaces, creep areas, and also roofings, providing smooth protection that gets rid of spaces and gaps where check these guys out air leakages frequently occur. Its capability to expand upon application ensures a tight seal, which is crucial for power effectiveness and wetness control.

Furthermore, spray foam insulation is available in various formulations, including open-cell and closed-cell kinds, linked here enabling for customized solutions based upon certain job requirements. Open-cell foam is lighter and better suited for soundproofing, while closed-cell foam offers superior insulation and structural stability, making it ideal for locations revealed to wetness.

In enhancement, spray foam can be used in hard-to-reach spaces, enhancing its viability for retrofitting existing frameworks. With the ability to stick to different substrates, including concrete, wood, and metal, spray foam insulation attracts attention as a functional alternative that satisfies the needs of modern-day structure methods.

Verdict

In final thought, spray foam insulation emerges as a premium option for insulation tasks due to its exceptional thermal resistance, energy performance, and capacity to produce closed seals that prevent dampness and mold growth. Picking spray foam insulation makes sure an extensive solution that fulfills the needs of modern building and construction and power effectiveness standards.

When it comes to attaining ideal energy effectiveness in property and industrial structures, spray foam insulation stands out for its superior insulation efficiency.The power efficiency advantages of spray foam insulation are considerable, further enhancing its charm as a leading option for building insulation.Investing in spray foam insulation yields substantial long-lasting cost savings, mostly with enhanced power performance.In verdict, spray foam insulation emerges as an exceptional alternative for insulation jobs due to its phenomenal thermal resistance, energy effectiveness, and capability to develop closed seals that prevent dampness and mold and mildew growth. Picking spray foam insulation makes certain a detailed service that meets the needs of modern building and construction and energy efficiency standards.